Garfield Buff Company cares about your safety. We have compiled guidelines to ensure you’re using Garfield buffing and polishing wheels in the safest possible way.

- Always make sure your work area is clean and free of obstacles, trip hazards, and debris.

- Wear proper protective gear. (Safety glasses, sleeves, gloves, etc…)

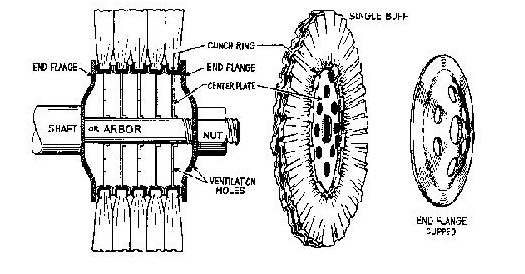

- Be sure the arbor hole diameter is the same diameter of the shaft. Example: 1¼” arbor hole on buffing wheel used on 1¼” diameter shaft.

- Make sure end flanges are sturdy and can exert adequate pressure to clamp buffing wheels securely.

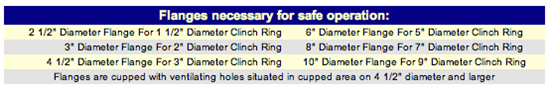

- Be certain end flanges are sufficient in diameter to extend to the outer tips of the metal clinch ring teeth and that the cup (bell) of the flanges have the concave surfaces toward the buffs. Do not use an end flange that is smaller than the clinch ring.

- Be sure thread on the arbor shaft is in good condition, that a nut can be fastened freely, and that the threaded portion of the shaft is sufficient to allow firm clamping of buff with the end flanges.

- Tighten the shaft nut securely using a proper wrench.

- Make sure the nut remains tight. Re-tighten if necessary.

- If spacers are used between buff sections, the outside diameter of the spacer must be large enough to cover the outside tips of the clinch ring teeth.

- If the spacer supports the buff center, be sure that the support area is the correct diameter and gives support to the entire inside diameter of the clinch ring.

- Be sure that the flange areas of the spacer will securely clamp the buff, and are not designed so that the support area or interlock portions prevent flange pressure on the buff. Buff must not spin on spacer or hub, as this can cause the clinch ring to break or the buff to burn.

- Always observe maximum recommended RPM. Do not use machines that exceed these limits. See our buffing speed chart for maximum speeds.

- Be sure the buffing wheel is adequately guarded. Observe machine manufacturer recommendations.

- Use proper securing devices for small and irregular shaped parts.

- Never reach over or allow clothing to get between the rotating buff and work piece fixture.

- Never leave a running machine unattended.

- If excessive vibration occurs, shut machine down immediately. Buffing wheels should never be run at speeds exceeding those shown on our buffing speed chart.

- Observe all manufacturer, compound supplier, and company safety recommendations.